From Bean to Bar — the origins of chocolate and how we use it at Makana Confections

Posted by Makana Confections on 18th Aug 2025

Chocolate doesn’t start as a candy bar in a wrapper — it starts on a tree. The story of chocolate is a mix of botany, ritual, chemistry and a whole lot of human creativity. Below is a friendly journey from the earliest uses of cacao to how chocolate is produced today — and how Makana turns those flavours into the goodies you already know and love.

Ancient beginnings — where chocolate came from

Cacao (Theobroma cacao, literally “food of the gods”) is native to the tropical rainforests of Central and South America. The Olmecs, Maya and Aztecs were among the first to cultivate and celebrate cacao. Back then cacao was mostly a ceremonial, bitter, frothy drink — sometimes flavoured with chilli, maize or spices — and even used as currency. When Europeans encountered cacao they sweetened and adapted it, setting the stage for the solid chocolates we enjoy today.

How chocolate was first made — hands, stone and fire

Early methods were wonderfully simple and very hands-on:

- Harvest — pop open ripe pods and scoop out the beans and sweet pulp.

- Fermentation — let the beans and pulp ferment for several days to develop flavour.

- Drying — sun-dried beans kept and concentrated flavours.

- Roasting & grinding — roasted beans were ground on stone surfaces into a paste.

- Mixing — paste combined with water, spices and sometimes corn to make a frothy drink.

That drink was complex, bitter and spicy — a far cry from the silky truffles and bars we gift today — but it’s the foundation of everything that followed.

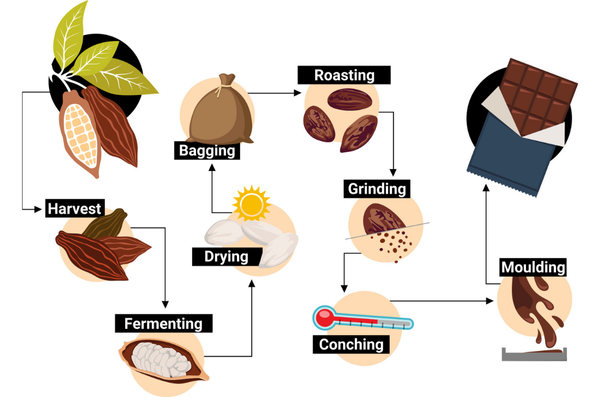

How chocolate is made today — the modern process (and where Makana fits in)

Modern chocolate production follows the same basic phases — harvest → fermentation → drying → processing — but with precise control and technology. Here’s a simplified flow of how modern chocolate makers bring those stages to life;

1. Harvesting → fermentation → drying

These steps still happen on farms in cacao-growing countries. Good fermentation and careful drying are where much of the final chocolate flavour is born.

These steps still happen on farms in cacao-growing countries. Good fermentation and careful drying are where much of the final chocolate flavour is born.

2. Roasting, cracking & winnowing

Roasting develops flavour; cracking and winnowing separate the edible nibs from the outer shells. The roasting profile greatly influences the final taste of chocolate.

3. Grinding / milling → cocoa liquor

The nibs are ground into a thick paste called cocoa liquor, which contains both cocoa solids and cocoa butter — the essential components of chocolate.

The nibs are ground into a thick paste called cocoa liquor, which contains both cocoa solids and cocoa butter — the essential components of chocolate.

4. Refining → particle size matters

Sugar (and milk powder for milk chocolate) is added and the mix is refined until particles are tiny. This is why a well-refined bar or a truffle melts smoothly on the tongue.

5. Conching → flavour & texture development

Conching is an extended process of mixing and heating that smooths the chocolate and allows unwanted flavours to dissipate. It develops both texture and depth of flavour, with timing adjusted to the desired chocolate profile.

6. Tempering → shine & snap

Tempering controls cocoa butter crystals so chocolate sets shiny with a satisfying snap. Whether we’re dipping shortbread or coating caramel, proper tempering is non-negotiable at Makana.

Tempering controls cocoa butter crystals so chocolate sets shiny with a satisfying snap. Whether we’re dipping shortbread or coating caramel, proper tempering is non-negotiable at Makana.

7. Moulding/enrobing & finishing

Tempered chocolate is poured into moulds or used to coat centres. This is where the chocolate meets makings: crunchy toffee, roasted macadamia, silky ganache.

Important note — what Makana actually does

Makana Confections does not produce chocolate from cacao beans. We purchase finished chocolate (usually high-quality couverture) from trusted suppliers, then transform that chocolate into the finished products you see in our shop and hampers.

Why this matters: buying finished chocolate lets us focus on technique — tempering, enrobing, making ganaches and fillings — and spend our time on flavour pairings (macadamia + sea salt, wine-infused truffles) and finishing touches. It also lets us choose chocolates with roast profiles, cocoa percentages and origins that best complement macadamia and toffee in our recipes.

Makana products — chocolate in real life

Once the finished chocolate arrives at the factory, here’s what we do;

1. Selecting the chocolate

1. Selecting the chocolate

We choose couverture (real cocoa butter content) with the flavour profile and cocoa percentage that suits each product — milk chocolate for Chocolate Dipped Macadamia Shortbread, dark chocolate for Espresso Stix.

2. Tempering

Tempering is critical. We heat and cool chocolate to get the right cocoa butter crystal structure so everything sets shiny, with a crisp snap, like our 72% Orange Snaps. Proper tempering also prevents bloom and helps coatings stay stable in boxes and hampers.

3. Dipping & coating

We don’t enrobe or mould — instead we transform finished chocolate by hand using three main techniques suited to each product.

We don’t enrobe or mould — instead we transform finished chocolate by hand using three main techniques suited to each product.

- Pinch-dipping (like our Chocolate Dipped Ginger): each ginger piece is dipped by hand and picked up in a pinch between thumb and finger before it’s set on a tray. This gives a thin, even coat with a handmade finish and lets us control how much chocolate sits against the ginger so the texture stays balanced.

- Fork-dipping (like our Truffle Medley): for ganache centres we use a dipping fork. The truffle is lowered into the bowl of tempered chocolate, lifted then picked up with a two-prong fork, tapped to remove excess chocolate and create a neat base before it’s deposited on a tray. This technique gives a glossy shell and a clean seam.

- Coating (like our Macadamia Butter Toffee Crunch): we coat by pouring milk chocolate on a slab of toffee and spreading it using a pallet knife, before finishing with roasted macadamia fines. This method preserves the toffee’s crunch while ensuring good coverage.

4. Ganaches & fillings

For truffles (like our Irish Cream Truffles) we make ganaches using finished chocolate + cream/flavourings. Ganache is cooled, hand-rolled, fork dipped in tempered chocolate and finished with decorations or inclusions.

Industrial vs Artisan approaches — why small batch matters to Makana

Industrial mass production often uses continuous machinery, emulsifiers and additives to optimise speed and shelf life. At Makana we prefer small-batch attention to technique: selecting the right couverture, tasting while we work, tempering carefully and finishing by hand. That hands-on care is how a macadamia shortbread becomes a Makana favourite.

Sustainability & giving back — real choices behind the bar

Chocolate supply chains have challenging issues — traceability, farmer incomes and environmental impacts. Makana supports better practices wherever possible (and has run charity campaigns in the past — such as donating a portion of Dark Chocolate Macadamia Butter Toffee Crunch sales to Youthline). Choosing responsible suppliers and investing in quality at every step helps protect the people and ecosystems that make chocolate possible.

Practical tips & a final nibble

- Store our chocolates in a cool, dry place away from strong odours; our Macadamia Butter Toffee Crunch stays crunchy for about eight weeks.

- If a bar looks “bloomed” (white streaks), it’s just fat or sugar migrating — not harmful, but less pretty. Proper tempering and storage prevents it.

- The melt in your mouth? That’s cocoa butter — designed by nature to melt just below body temperature.

Chocolate’s journey from sacred Mesoamerican drink to the handcrafted treats in our hampers is a story of culture, curiosity and craft. Whether you’re tucking into a piece of Classic Macadamia Bark with your afternoon tea or gifting a Dark Decadence hamper, every bite is the sum of choices from farmer to conche — and the Makana team is proud to play our part.